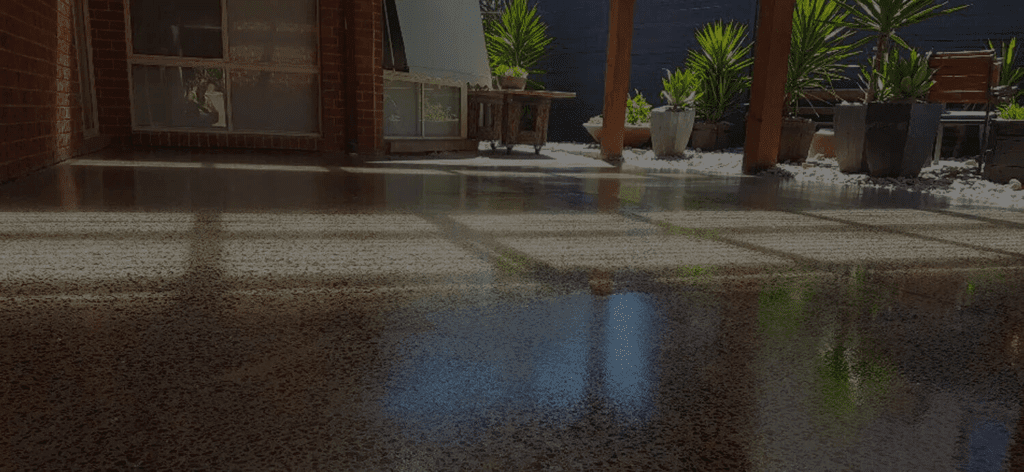

Melbourne's Mechanically Polished Concrete Solutions

Mechanically polished concrete remains unaffected by surface contaminants that can dull the shine and brightness of even the most beautiful flooring. Our experts use state-of-the-art equipment that reveals the true beauty of your flooring, while making them ready for any further flooring treatment. The resulting flooring sustains lesser scratches, requires minimal maintenance and is eco-friendly.

Mechanically polished concrete has become one of the most popular flooring options in the modern architecture and design industry. It provides a polished surface that can be a testament to the sophistication and durability of the flooring. This innovative technique helps transform an ordinary concrete floor into a sleek and glossy masterpiece. Mechanical polished concrete can also be customised according to the variety of spaces.

Through a meticulous process that involves abrasives and polishing tools, the concrete’s surface provides a mirror-like finish, accentuating its natural beauty. Apart from its visual appeal, this method of mechanical polished concrete also increases the longevity of the floor and reduces the need for additional flooring materials.

With our 40 years of experience in the industry, we have provided our clients with satisfactory jobs by delivering high-quality mechanical polished concrete flooring solutions. Elevate your residential or commercial spaces with our family-owned business, GrindWorks and experience our commitment to unique craftsmanship and innovation.

Significance of Mechanical Polished Concrete

There are many benefits when you choose concrete polishing for your modern flooring solutions, such as:

- Durability and Longevity: Polished concrete has the power to enhance the lifespan of flooring by creating a dense and abrasion-resistant surface. This will provide longevity even if it is in high-traffic areas of residential or commercial spaces.

- Low Maintenance: Polished surfaces can resist stains, dust, and even moisture. So, you won’t need to worry about extensive maintenance, and it also reduces the long-term costs associated with the upkeep.

- Eco-Friendly: We use the existing concrete base to reduce the need for new materials, which aligns with sustainable building practices.

- Health and Hygiene: The non-porous nature of mechanically polished concrete hinders the growth of mould, allergens, and bacteria, promoting a healthier indoor environment.

- Energy Efficiency: The reflective properties of polished concrete help improve natural lighting, reducing the need for artificial lighting and consequently lowering energy consumption.

The Process of Mechanical Polishing

We have an 18-step mechanical polishing procedure behind Grindworks polished concrete. Our process ensures that our clients get a visually stunning end result and a flooring solution that stands the test of time.

Our process includes:

- Grinding: We start with precision grinding. We tailor the concrete according to the desired exposure and then create a base for a smooth finish.

- Grouting: Next comes a comprehensive 3-step grouting process. It’s strategically designed to fill every crack, hole, and imperfection in the concrete. This ensures a flawless and level surface.

- Chemical Fortification: Concrete densifiers are then strategically applied, which chemically solidify the floor. This is an important step to enhance surface hardness as it contributes to the polish’s longevity and strengthens the concrete structure against wear and tear.

- Polishing: The heart of the process lies in the polishing stages. Employing a series of cutting-edge polishing resins, we artfully refine the surface, progressively achieving the desired gloss level. As a result, you get a visually striking, mirror-like finish that radiates sophistication.

Our polished concrete floors stand as a formidable barrier against scratching, foot traffic, and the pitter-patter of pets. Whether you are planning for a new construction or revamping your existing concrete spaces, we ensure that each step of the process is executed with precision and unparalleled quality.

Maintenance Tips for Mechanical Polished Concrete

Here are a few tips from us on how to protect and enhance the longevity and beauty of your mechanical polished concrete floor:

- Dust and debris can gradually wear down the polished surface. Adopt a routine cleaning schedule using a soft-bristle broom or a dust mop to remove loose particles.

- For a deeper clean, use a damp mop with a neutral pH cleaner. Harsh chemicals can compromise the sealer and dull the polished finish.

- Place soft pads under furniture legs to prevent scratching and abrasion when moving or rearranging items.

- Depending on the foot traffic and use, periodically check the condition of the sealer. If it shows signs of wear, consider reapplying to maintain optimal protection.

- Mechanical polishing creates a self-sustaining shine. Avoid wax or polish; they can create a slippery surface and may not adhere well to the polished concrete.

- Periodically, engage professionals for a deep clean and assessment of the floor’s condition. Professional maintenance can address any potential issues and renew the polished finish.

Choosing a Mechanically Polished Concrete Service Provider

GrindWorks has been working with concrete flooring requirements for years, and our experts are well-acquainted with mechanically polishing concrete flooring. We ensure that our services leave a lasting impression and make you want to always admire the quality of the flooring. Our services are cost-effective and aimed at delivering exceptional quality that lasts for years to come.